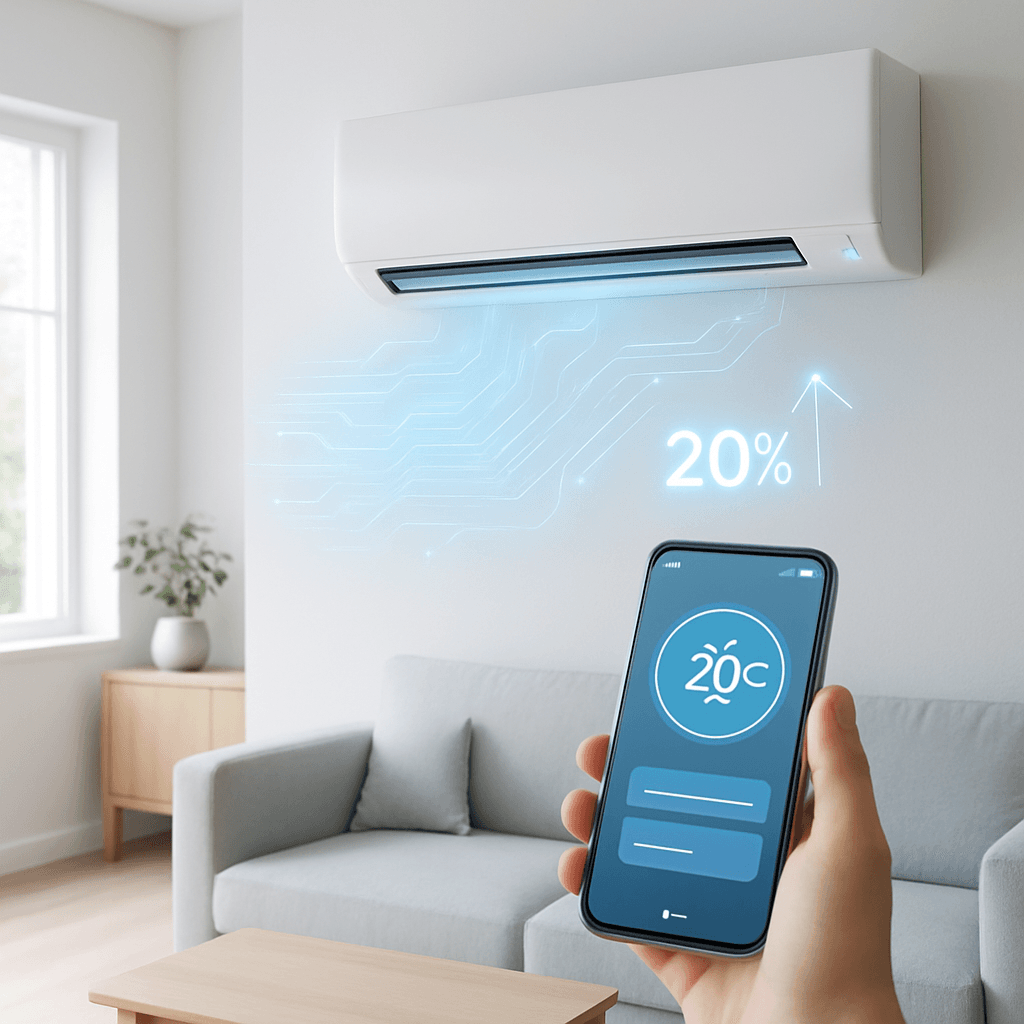

Quilt just proved that your home's heating system can get Tesla-style upgrades. The climate startup pushed a software update that instantly boosted heating and cooling capacity by 20% for every heat pump already installed in customers' homes. It's the first over-the-air performance upgrade in HVAC history, bringing software-defined improvements to an industry that's barely touched units after installation.

Quilt just pulled off something that sounds impossible in the HVAC world - they made existing heat pumps more powerful without touching a single wrench. The climate startup pushed a software update last week that boosted heating and cooling capacity by over 20% for units already humming away in customers' homes. It wasn't a bug fix or efficiency tweak. This was a genuine performance upgrade that happened overnight. "From the very beginning, we wanted to design systems to be continuously improved, updated over the air," CEO Paul Lambert told TechCrunch. "It's a pattern that's happened in EVs and gotten a lot of traction, but no one had really done that before in HVAC." The numbers tell the story. Originally, Quilt's outdoor units delivered up to 19,700 BTUs of cooling per hour and 20,500 BTUs of heating. After the update, those figures jumped to 24,000 BTUs for cooling and 25,200 BTUs for heating - all through software and firmware changes. Heat pump expert Drew Tozer believes this marks the industry's first capacity-boosting OTA update. In traditional HVAC, once equipment gets installed, it only gets attention when something breaks. But Quilt's team didn't come from traditional HVAC backgrounds. They were recruited from Nest, Google, Apple, and Tesla - companies where frequent updates are standard operating procedure. Isaac McQuillen, who led the capacity project, previously managed thermal systems at Lucid Motors. "We got some feedback from both installation partners and some customers that it'd be really useful if we were able to have a slightly higher maximum operating capacity," McQuillen explained. Customers with larger living rooms or open floor plans were pushing their units harder than expected. The magic happened because Quilt had over-engineered their sensors from day one. While most residential HVAC systems use basic monitoring, Quilt packed in additional pressure sensors, higher-accuracy temperature sensors, and current monitoring throughout both indoor and outdoor units. That extra data revealed headroom the team didn't know existed. After months of in-house testing to validate performance and reliability, they pushed updates to both software and firmware running on the main processor and microcontrollers scattered throughout the system. The networking hardware they'd built in made the whole process seamless. Lambert describes it as "software-defined HVAC," borrowing terminology from the automotive world where Tesla pioneered over-the-air performance boosts. The approach isn't free - those premium sensors and networking components add to the bill of materials. But Lambert sees it as an investment that pays dividends. "There's the upfront capital cost of the sensors, but we think there's so much value to be gained from that extra data," McQuillen said. "The hard part," Lambert added, "is knowing how to build all the integration around it with the software and all the systems working together." The smart money sees this as just the beginning. Instead of designing entirely new models to serve customers with higher capacity needs, Quilt can now expand their addressable market with a software push. It's the kind of scalable approach that makes venture investors happy and customers feel like they're getting continuous value from their purchase. Looking ahead, this could reshape how the entire HVAC industry thinks about product development and customer relationships. If your heat pump can get better over time, why wouldn't you expect the same from every major appliance in your home?