Climate tech startup Terraton just raised $11.5 million to solve biochar's biggest problem: scaling production. The company wants to franchise carbon-capturing biochar facilities like McDonald's franchises burger joints, betting that a "business-in-a-box" model can finally unlock this promising climate technology's potential at scale.

Terraton just cracked the code on one of climate tech's most frustrating puzzles. The startup announced an $11.5 million seed round to franchise biochar production facilities globally, bringing McDonald's-style systematization to a technology that's been stuck in boutique mode for years. Lowercarbon Capital and Gigascale Capital led the round, with participation from ANA Holdings' ANA Future Frontier Fund and East Japan Railway Company's Takanawa Gateway Global Co-Benefits Fund. Notable angels include Google's Jeff Dean and OpenAI board member Bret Taylor.

The timing couldn't be better. Corporate buyers are hungry for biochar carbon credits but can't find enough suppliers to meet demand. "When we talk to the big buyers like Microsoft, Google, Airbus — those sort of companies — they want to buy more, and they can't find more places to buy it from," CEO Kevin Gibbs told TechCrunch. That supply crunch represents a massive opportunity for anyone who can crack scalable production.

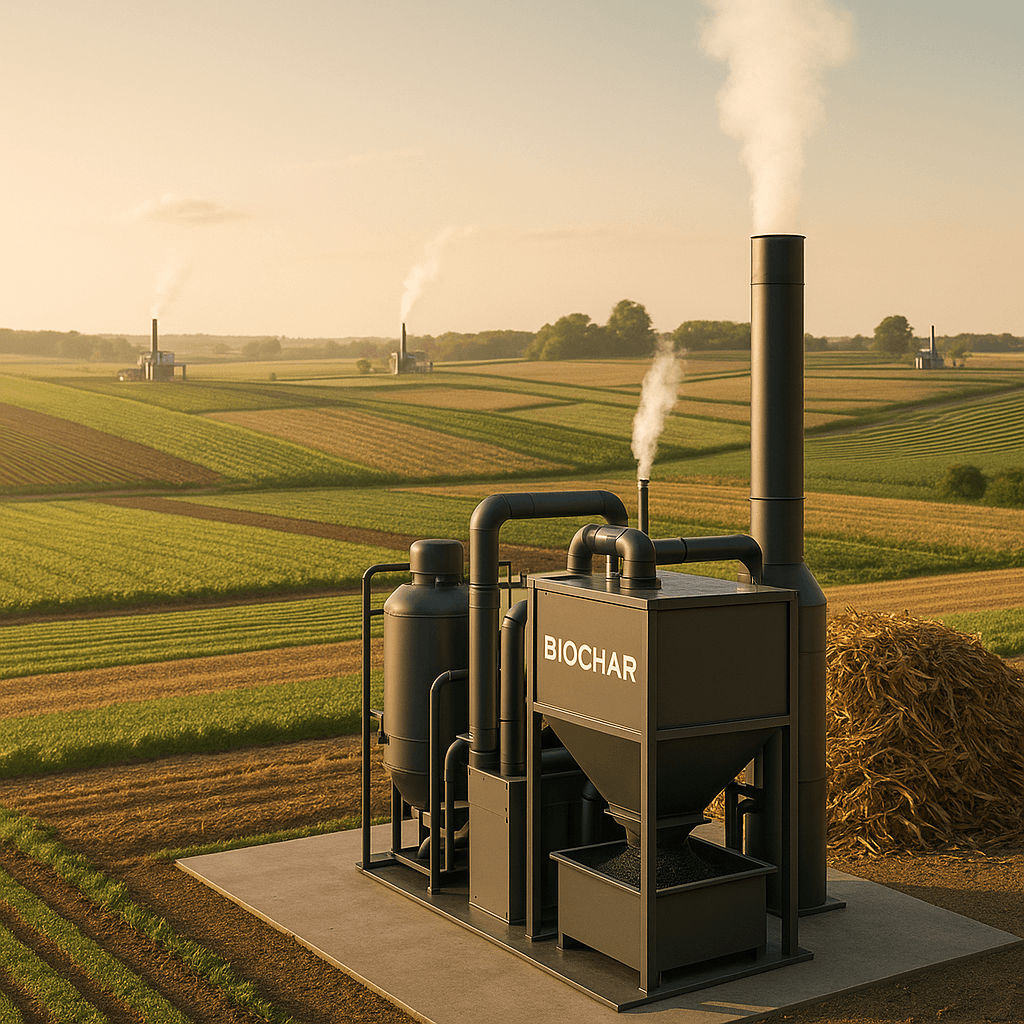

Biochar works by burning agricultural waste in oxygen-free environments, creating a charcoal-like substance that stores carbon in soil for centuries while improving agricultural yields. The science is proven, but execution has been hampered by one-off projects that never scale beyond their initial facility. "Most biochar facilities, people have only ever built one," co-founder Greg D'Alesandre explained to TechCrunch. "They've never learned and progressed."

Terraton's franchise approach flips that dynamic entirely. Instead of building facilities themselves, the company partners with local businesses who understand regional agricultural waste streams and farmer relationships. Terraton provides the technology blueprint, operational software, and ongoing support — essentially everything a franchisee needs to launch and scale a biochar operation. The model creates natural geographic distribution since biochar facilities must be located near waste sources to minimize transportation costs.

The company has already proven the concept with two operational facilities in Africa. One in Ghana processes cocoa waste, while another in Kenya handles nut processing residue. Together, these facilities are expected to remove 20,000 metric tons of CO2 annually — demonstrating both the technology's effectiveness and the franchise model's viability across different agricultural contexts.