Samsung just became the first major tech manufacturer to achieve zero waste to landfill across every single global production site. The company's 22 factories now divert 100% of their waste from landfills, recycling 1.32 million tons of materials in 2024 alone - equivalent to taking 260,000 garbage trucks off the road.

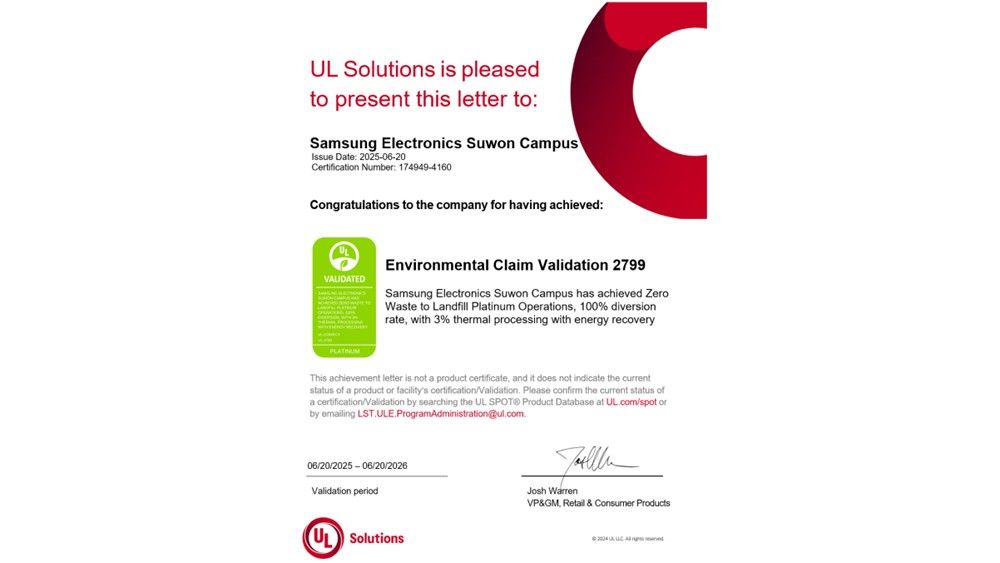

Samsung just rewrote the playbook for sustainable manufacturing at scale. The tech giant announced it's achieved UL Solutions' coveted "Zero Waste to Landfill" Platinum designation across every single one of its global manufacturing sites - a feat that puts the company ahead of virtually every other major tech manufacturer.

The milestone caps off a three-year push that began with Samsung's Environmental Strategy announcement in 2022. Since then, the company has systematically transformed how it handles the millions of tons of waste generated from producing everything from smartphones to semiconductors. The Platinum rating means 100% landfill diversion - not 95% or 99%, but literally zero waste going to dumps.

"This represents a major milestone in our environmental management strategy," Junhwa Lee, Executive Vice President and Head of Global EHS Office at Samsung's DX Division, told reporters. The achievement required overhauling waste management systems across 22 domestic and international manufacturing facilities, from South Korea to Vietnam to Hungary.

The numbers tell the story of just how massive this undertaking was. Samsung recycled approximately 1.32 million tonnes of waste in 2024 alone - equivalent to what 260,000 five-tonne garbage trucks would haul. But it's not just about volume. The company's been developing sophisticated recycling technologies that turn semiconductor production waste into reusable materials.

Take their chip manufacturing process, where waste liquids are now repurposed as cleaning agents for air pollution scrubbers and water treatment facilities. Even the adsorbents, activated carbon, and catalysts used to control air pollutants get regenerated and reused as raw materials for identical applications. It's a closed-loop system that would make any circular economy advocate proud.

The transformation wasn't just about installing better equipment. Samsung had to retrain workers across multiple continents on refined waste separation systems. Food waste and paper get composted at facilities in Thailand, India, Malaysia, and Mexico. Construction waste gets converted to alternative fuels in Vietnam, Malaysia, and the US. Even e-waste and battery residues are repurposed for solid fuel production in Indonesia.